-

Heavy steel forgings

-

Open die forging

-

Alloy steel forgings

-

Ring flange, rolling ring

-

Forged steel shaft

-

Gear forging, gear ring

-

Forged cylinder, cylinder forging

-

Carbon steel forgings

-

Stainless steel forgings

-

Crankshaft forging, forged crankshaft

-

Roller forging, forged roller

-

Forged spindle, turbine spindle

-

Marine rudder, forging for marine

-

Steam turbine rotor forging

-

Tube sheets

-

Machined parts

-

Olaf kyrre monradI am sure that all customer so meet her will be very satisfied with her good service.

Olaf kyrre monradI am sure that all customer so meet her will be very satisfied with her good service.

Mining machinery gear guides, gear transmission, rack, gear rack with carbon alloy steel

| Place of Origin | China |

|---|---|

| Certification | MTC, Chemical composition, mechanical properties, UT, MT, dimension report, heat treatment record et |

| Minimum Order Quantity | 1 piece |

| Packaging Details | Individual plastic wrapping, fumigation-free wooden pallet or steel shelf. All wood to fumigated in |

| Delivery Time | 30 days or as per the exact product |

| Payment Terms | 30% prepayment by T/T, the balance against the receipt of the correct test certificates or as per cu |

| Supply Ability | 100 pieces |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

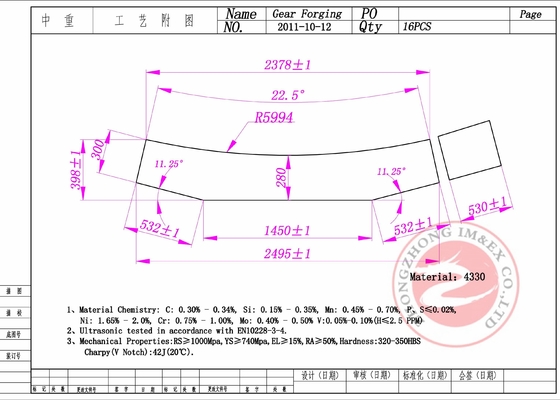

xCarbon Steel Gear Rack Open Die Forging Heat Treatment , EN10228 / ASTM A388

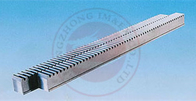

Mining machinery gear guides, gear transmission, rack, gear rack with carbon steel, alloy steel or stainless steel

Quick Detail:

1. Mining machinery gear guides, gear transmission, rack

2. Alloy steel, carbon steel or as per customer’s requirements

3. Good quality, good service, short delivery time

Description:

Rack into the rack spur and helical gear racks, respectively, with the spur gear and helical gears used in pairs; rack tooth profile is a straight line rather than involute, the equivalent of the pitch circle radius is infinite cylindrical gear.

It conforms to the standard of ASTM, EN, DIN, GB.

The manufacturing equipment is 30~185MN hydraulic press, the forging ratio >3, the technical condition is in accordance with the standard of ASTM, EN, DIN, GB.

Specifications:

|

Description |

Mining machinery gear guides, gear transmission, rack |

|

material |

Alloy steel (4140, 42CrMo4, 4340,18CrNiMo7-6 etc.), carbon steel, stainless steel etc. |

|

Material standard |

ASTM ,GB,EN,ISO |

|

Dimension |

Max.W: 2000mm Max. Length: 15000mm |

|

Weight |

Max. 50 ton |

|

Smelting Process: |

EF+LF + VD |

|

Process |

Ingot→heat → forging → Heat treatment (Normalizing+ tempering) → Inspection →rough machining →UT →2nd Heat treatment →finishing machining →Inspection |

|

UT standard |

ASTM A388 or EN10228 |

Applications:

Used in mining machinery, metallurgical machinery, offshore platforms, rail connections and other gear industry

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time” delivery.

Why us?

1. Short production time, “in-time” delivery;

2. We can provide the steel forgings whatever size, material or type as per your requirements;

3. Good quality and competitive price

Years of forging, machining, precision gears, rack of production experience and perfect processing equipment, is the foundation of our product quality control.

The production flow chart:

![]()

![]()

![]()

![]()

![]()

![]()

![]()