-

Heavy steel forgings

-

Open die forging

-

Alloy steel forgings

-

Ring flange, rolling ring

-

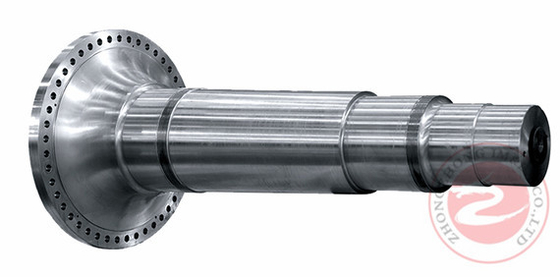

Forged steel shaft

-

Gear forging, gear ring

-

Forged cylinder, cylinder forging

-

Carbon steel forgings

-

Stainless steel forgings

-

Crankshaft forging, forged crankshaft

-

Roller forging, forged roller

-

Forged spindle, turbine spindle

-

Marine rudder, forging for marine

-

Steam turbine rotor forging

-

Tube sheets

-

Machined parts

-

Olaf kyrre monradI am sure that all customer so meet her will be very satisfied with her good service.

Olaf kyrre monradI am sure that all customer so meet her will be very satisfied with her good service.

Q345D Rotor locking plate wind power generator parts,Steam Turbine Rotor Forging shaft

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Alloy Steel |

|---|

| Material: | Q345D | Forging Equipment: | 3500T Hydro Press |

|---|---|---|---|

| Melting Process: | EF-LF-VD | Forging Ratio: | ≥4:1 |

| Max Weight: | 5T | MOQ: | 10PC |

Q345D Rotor locking plate wind power generator parts,Steam Turbine Rotor Forging

Products reference:

| Material | Q345D |

| Forging equipment | |

| |

| Melting process | EF-LF-VD |

| Process technology | |

| Forging ratio | ≥4 |

| Applicable standard | ASTM,ASME,DIN,JIS,ISO,BS,API,EN |

| Executive standard | JB/GB/EN/DIN/JIS/ASME/ASTM/ISO |

| Certification authority | ISO9001,PED (TÜV) |

| Delivery term | Each product is qualified,no defect of material and processing,fully meet the mechanical property |

| Test equipment | Spectrograph,UT,MT test device,tensile and impact test machine,metalloscope,outside micrometer,bore dial indicator,hardness test device |

| Service | Our service included the forging, process, heat treatment, finish machining, package, local logistics, customers clearance and maritime transport. We took the customer’s requirements as the principal thing, and pay attention on the products quality. |

Custom properties:

| Chemical composition | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| Q345D | ≤0.18 | ≤0.50 | ≤1.70 | ≤0.030 | ≤0.025 | ≤0.30 | ≤0.50 | ≤0.10 | ≤0.30 |

| Mechanical property | Dia.(mm) | TS/Rm(Mpa) | YS/Rp0.2(Mpa) | EL/A5(%) | RA/Z(%) | Type Of notch | Impact energy | HBW |

| Q345D | Ф20 | 470—630 | ≥335 | ≥20 | ≥25 | V | ≥40J(-20℃) | / |

Process procedure:

Forging process flow quality control: Raw material steel ingot into warehouse(test the chemical content) → Cutting→ Heating(Furnace temperture test) → Heat treatment after forging(Furnace temperture test) Discharge the furnace(blank inspection)→ Machining→ Inspection(UT,MT,Visal diamention, hardness)→ QT→ Inspection(UT, mechanical properties, hardness, grain size)→ Finish machining→ Inspection (dimension)→ Packing and Marking(steel stamp, mark)→ Storage![]()

![]()

![]()

Commerce clause:

| Max weight | 5T |

| MOQ | 1 pc |

| Delivery time | 30-50 days |

| Package | Film,wooden case |

| Delivery term | FOB;CIF |

| Payment term | T/T,LC |

| Transportation | vehicle,ocean,air |

Keywords:

Rotor locking plate is the important parts of wind power generator that can brake and lock the rotor rotating.common material is Q345D or as inquiry,after forging it needs to be machined at horizontal lathe,deep hole drilling machine,floor type boring machine.after machined it need to be tensile and impact tested.![]()

![]()

Advantage:

High-precision dimensional tolerance;

Excellent mechanical properties;

Produce different dimension based on customer’s requirements;

Advanced manufacture equipments and inspection devices;

Excellent technical personality;

Control the production procedure strictly;

Pay attention on the package protection;

Quality full service.![]()